Car Care Tip – How Broken Valve Springs Can Affect Your Engine

Today we will learn about one of the main parts of an engine’s valve train. In an engine many parts work together and achieve the goal of converting chemical energy of fuel into mechanical energy. These parts are bolted together and the combination of all these parts is known as engine. Today I am going to tell you about one of the key components required to make an engine operate.

To control the inlet and exhaust of internal combustion engine, valves are used. The number of valves in an engine depends on the number of cylinders. Multiple valves are used for each cylinder some for inlet of air-fuel mixture inside the cylinder and others for exhaust of combustion gases. The valves are fitted in the port at the cylinder head by use of a strong spring. This spring keeps them closed. Each valve within the cylinder head has at the least one spring. The valve spring exerts stress against the valve retainer to maintain the valve closed. When the rocker arm in a pushrod engine, or the cam follower in an OHC engine moves and pushes the valve open, the strain exerted from the spring increases. The strain maintains valve lash within the valve train, and pushes the valve shut once again as being the rocker arm or follower rotates away from your valve.

Broken Valve Springs

Broken or weak valve springs in an engine can cause many different drivability and performance problems. Broken valve springs cause excessive valve noise, compression loss and can cause severe internal engine damage. The actual breaking of the valve springs is not always the most serious consequence. Actions following the breaking cause the most serious damage to the engine. When spring breaks, it may collapse just enough to allow the valve to drop into the cylinder, where the piston may strike it. In addition, the valve stem locks or keepers may release the valve and allow it to drop into the cylinder, causing severe damage to the piston, cylinder head, and other nearby parts.

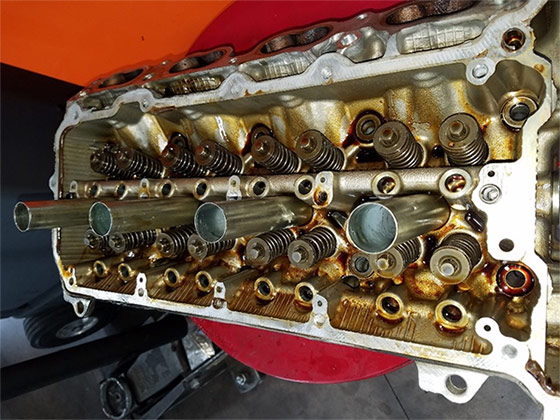

We recently had a vehicle at our Happy Valley location with a heavy cylinder misfire condition present and had a check engine light on due to the misfire. Multiple diagnostic checks and tests were performed. These tests included compression tests and cylinder leak down tests. We had determined that one of the 8 cylinders had zero compression and that one of the intake valves was unable to hold the adequate pressure required to allow the cylinder to “fire” properly. Removal of the valve cover assembly had given the technician the ability to view the valve springs. Visual inspection had discovered a broken valve spring on the cylinder in question.

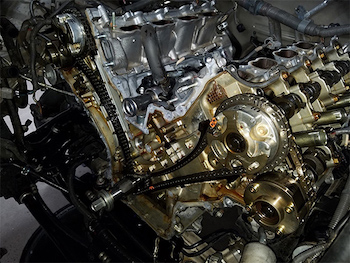

In order to perform repairs to this vehicle cylinder head removal was required. Once removed all 32 valve springs were replaced and head assemblies were pressure tested at a local machine shop to determine proper function prior to installing cylinder head assemblies back on the vehicle. All 32 springs were replaced due to the vehicles mileage and the high probability that more springs could have been weak and may break in the near future. Once the engine was re assembled with all new gaskets and new fluids were installed the vehicle was test driven multiple times to make sure everything was working correctly. It was then released to the customer who was extremely satisfied and ready to drive many more miles.